BASIC BUILDING STRUCTURE:

Components of building: A building can be broadly divided into two parts

1) Sub structure, 2) super structure.

The portion of the building below the surrounding ground is known as “sub structure”.

The portion above the ground is termed as “super structure”

The components of a building can be broadly summarized as

1) Foundation, 2) Plinth, 3) Walls, 4) Columns, 5) Floors, 6) Doors, windows, ventilators, 7) Stairs, 8) Roof, 9) Building finishes, 10) Building services.

Foundation: It is the lowest part of a structure which provides a base for the super structure.

These term includes the position of the a structure below the ground level as well as the artificial arrangement of concrete blocks, pipes, rafts, grillage, etc,

Provided to transmit the loads of the structure including the dead weight of the structure itself to the soil below.

Purpose of foundation:

It is often misunderstood that the foundation is provided to support the load of the structure

Infact, it is a device to transmit the load of the structure to the soil below.

Foundation is provided for the following four purposes:

1. To distribute the weight of the structure over large area. So, as to avoid overloading of soil beneath.

2. To provide a leveled surface for building operation.

3. To take the structure deep into the ground and thus, increase its stability preventing over turning.

The provision of foundation is made in such away that the soil below the foundation is not stressed beyond it’s save bearing capacity. Depending upon the type of soil existing at site, its sate bearing capacities and the type of building which is required to be constructed, A structures may need shallow(not so deep) or deep foundation.

In case of load bearing walls the foundation could be in the form of spread footing.

For frame structure the foundation could be in the form of independent column footing.

Plinth: The horizontal projection of stone or brick provided at the base of the wall above ground level is known as “plinth”. It rises the level of the ground floor of the building above natural ground level is known as “plinth level”. With the aim of projecting the ground floor from rain water and other weather effects.

Walls: Walls are provided to enclose or to divide the floor space in desired pattern.

In addition walls provide privacy security and gives protection against sun, rain, cold and other adverse effect of weather.

The division of floor space varies according to the functions required to be performed in the building.

In a well planned layout, the wall divides the space in such a manner so as to achieve maximum carpet area and minimum area of circulation.

Walls are constructed by use of building units like bricks, stone, concrete blocks (hollow or solid)

The building units are bounded together with mortar in horizontal and vertical joints and the construction is known as “masonry”.

When bricks are used as building units it is known as “Bricks Masonry”.

When stones are used as building units it is known as “Stone Masonry”.

Walls can be broadly divided into two categories

1. Load bearing walls

2. Non load bearing walls

1. Load bearing walls: A walls designed to carry superimposed load from the floor and roof is termed as “L.b.w”.

2. Non load bearing walls: An n.l.b.w. on the other hand causes its own weight and is not designed carry any superimposed load from the structure. They are normally provided as the partition wall.

Columns: A columns may be defined as an isolated vertical load bearing member. The width of which is neither less than its thickness or more than four time its thickness.

Pier: Pier is a vertical load bearing member similar to a column except that it is bounded into load bearing walls.

At the sides to form an integral part an extends to the height of the wall.

A pier is introduced to increase the stiffness of the wall to carry additional load or to carry vertical concentrated load. Pier also strengthens the wall to resist lateral pressure without buckling.

Floors: floors are flat supporting elements of a building. They divide a building into different level there by creating more accommodation on a given plot of land. The basic purpose of a floor is to provide a firm and dry platform for people. And other items like furniture’s, stores, equipment, etc. floor is generally reforded to by its location. A floor provided for accommodation below the natural the ground level is termed as the basement floor. A floor immediately above the ground is termed as ground floor. And all other floor such as 1st, 2nd floor etc. are termed as upper floor. A floor basically consist of 2 parts namely

1. Sub floor, 2.Flooring.

The sub floor is the structural component of the floor which support all the loads (dead and superimposed) and flooring is covering layer of desired specification (cement –concrete, terrazzo, tiles etc) provided over the sub floor to serve as a finishing layer.

Door, Windows and Ventilators:

A door may be defined as a barrier secured in and opening left in a wall to provide usual means of access to a building, room or passage this can be termed as most contently used moving component in a building.

A door normally consist of two component namely

1. Door frame, 2. Door shutter.

The door frame is permanently help in position and fixed to the masonry of the opening with the help of hold fast or rawl plugs. Shutter is the moving part of the door. Doors are made out of material like wood, steel, aluminums, plastic, flexible, rubber etc. they can be side hung, sliding, folding, revolving, or rolling type. Depending upon the functioning requirements.

A window may be defined as an opening made in walls for the purpose of providing day light, vision, & ventilation. Similar to door a window has framed and one or more shutter. The shutters are normally fitted with glass or similar transparent material. The windows can be side hung, top or bottom hung, lowered type, pivoted, metal window, bay windows, dormer window, sky light window. The shutter can be fully glazed, paneled & glazed or fully paneled type.

Stairs: A stair may be defined as a structure comprising of a number of steps connecting one floor to another. The stair must be constructed in such a manner that it is safe and comfortable to use and it should be so located as to permit easy communication. Stairs may be made from material like timber, bricks, steel, reinforced concrete etc. The selection of a type of material to be used depends upon the aesthetical importance, funds availability and fine resistance qualities desired.

Roof: It is the uppermost component of a building and its main function is to cover the space below and protect it from rain, snow, sun, wind, etc. A roof basically consists of two components namely

1. The roof decking, 2. The roof covering

The roof decking is the structure component which supports the roof covering. A roof can be either flat, pitched or curved in shape. The choice of the type of roof is made keeping in view of the location of the building, weather condition, funds available and function and aesthetics requirement. The structural component or roof decking in case of pitch roof is generally a rest, in case of curve roof it is a shell or dome and in case of flat roof it is a flat slab. The roof covering or roofing which is provided over pitched roof could be in the form of tiles, states, A.C sheets, G.I sheets etc. In case of flat roofs, the roof covering is termed as terracing, which could comprise of a layout of varying thickness of material like lime concrete, mud phuska etc. the terracing serves dual purpose I.e. 1.of providing suitable slopes on the roof top for draining of rain water 2. Of acting as consultation layer for providing thermal comport of the users of the space below.

Footing: A foundation unit constructed in bricks work, masonry or concrete under the base of a wall or column for the purpose of distributing the load over a large area.

Loft: An intermediary floor space created by introduction of a slab between floor and ceiling of a room. Passage and wherever it is provide with maximum clear height of 1.5mt. For storage purpose only.

Parapet: A low wall or railing build along the edge of roof or a floor.

Mezzanine floor: An intermediate floor between two floor level above ground floor and at least one side of it should form an integral part of space floor.

Porch: A covered surface supported on pillars for the purpose of pedestrian or vehicle approach to the building.

Chajja or sunshades: A sloping or horizontal structural over hand usually provided over opening on external wall for protection from sun and rain.

External wall: An outer wall of the building not being partition wall even through a joining to a wall of another building and also means a wall abutting on an interior open space of any building.

Court yard: A space permanently open to the sky enclosed fully or partially by building and may be at ground level or any level within or adjacent to a building.

Partition: An interior non load bearing wall.

Storey: The position of a building included between the surface of any floor and the surface of the floor meant above it.

Drain: Line of pipes including all fittings and equipment such as manholes, inspection chambers, traps. Used for drainage of the building.

Drain shall also include open channel used for carriage of surface bottom.

Drainage: The removal of any liquid by a system constructed for their purpose.

Balcony: A horizontal cantilevered projection including a hand rail or balustrade to serve as passage or sitting out place.

Sill: It is the horizontal member of brick stone, concrete or wood provided to give support for the vertical member of a window. It is also employed for the purpose of shielding of rain water from the face of the wall immediately below the window opening.

Lintel: A horizontal member of stone, bricks, wood, steel, or R.C.C. uses to support the masonry or load above an opening.

Coping: Coping is a covering placed on the exposed top of an external wall. It is essentially provided to present seepage of water. The joints of the top most course of the wall. It may be of concrete, stone, bricks or terracotta.

Throating: It is a term applied to the groove that on the under side of a projection course of masonry in order to check the seepage of rain water from the under side of projection portion.

Cantilever: The projection of the beam which support the balcony.

BRICKS:

TECHNICAL TERMS:

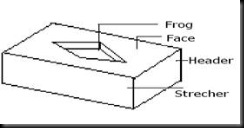

Header: It is a brick or stone which lies with its greatest length at right angle to the face of the work. In case of stone masonry, header is sometime is known as “True stone”. The course of brick work in which all the bricks are laid as header is known as “header course”.

Stretcher: It is a brick or a stone which lies with its longest side parallel to the face of the work. The course of brick work in which all the bricks are laid as stretchers is known as “stretcher course”.

Course: A course is a horizontal layer of a bricks or stones.

Bed: This is a surface of a stone or a brick perpendicular to the line of a pressure. It indicates the lower surface of a brick in each layer of course.

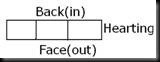

Back: The inner surface of a wall which is not exposed is called “Back”.

Face: The exterior of a wall exposed to weather is known as “Face”. The material used in the face of the wall is known as facing.

Hearting: It is the exterior portion of wall between the face and back.

Joint: It is a junction of two or more bricks or stones. If the joint is parallel to the bed of brick or stones in a course. Then it is known as “Bed joining”. The joints which are perpendicular to the bed joint are known as “vertical joint”, “side joints”, “and joints”.

Bond: This is the method of arranging bricks. So, that the individual units are tied. (Bonded) together. Bonding is essential to eliminate continuous vertical joints both in body as well as the face of the wall.

Spalls: These are the chips of stones used for filling (The gaps between bricks) interstices in stone masonry.

Bat: It is the portion of brick cut across its width.

Frog: It is an indentation (depression) on the top face of a brick made with the object of forming a key for the mortar. This reduces the weight of the brick also.

Plinth: It is a horizontal course of stone or brick provided at the base of the wall above the ground level. It indicates the height of the ground floor level above the natural ground level. It protects the building from dampness.

Plinth Course: It is the top most part of the plinth masonry.

String Course: It is the horizontal projected course of masonry projecting from the face of the wall for shedding rain water of the face. It imparts an aesthetic appearance to the structure and is generally provided at every floor level.

Sill: Sill is the horizontal member of stone, concrete stone or wood employed for the purpose of shedding of rain water. From the face of wall immediately below the opening. It support to vertical member of a wooden frame.

Lintel: It is a horizontal member of stone, brick, wood, iron, or R.C.C used to support the masonry or load above an opening.

Jambs: These are the vertical sides of an opening for doors and windows. These may be plane or may be provided with to resist receiving the door frame or window frame.

Reveals: These are the exposed vertical surfaces left on the sides of an opening after the door or window frame is fixed in position.

Cornice: It is the projecting horizontal ornamental course near the top of the building at the junction of wall and building.

Blocking Course: It is the top most course of a stone masonry provided immediately above the corners to prevent the tendency of the cornice to over turn.

Buttress: It is the sloping or stepped masonry projection from a tall wall intended to strengthen the wall against the thrust of the roof.

Pier: It is a isolated vertical mass of stone or brick masonry to support beams, lintel etc.

Template: Pieces of stones placed under the end of the beam to distribute weight on to a greater area.

Corbel: It is an extension of one or more course of stone or brick from the face of a wall to serve as a support for wall plate.

Queen Closure: It is the portion of a brick obtains by cutting a brick lengthwise into two portions.

King Closure: It is the portion of a brick obtains by cutting of the triangular pieces between the centre of one end and the centre of one side.

Beveled Closure: It is the portion of a brick obtains by the whole length of the brick is beveled for maintaining half width at one end and full width at other end.

Shapes of bricks: Ordinary bricks are rectangular solids. But sometimes bricks are given different shapes to make them suitable for particular type of construction. Following are such few types of bricks.

1. Bull nose brick: A brick molded with a rounded angle is termed as a bull nose. It is used for a rounded quoin. The centre of the curved portion is suited on the long center line of brick.

2. Channel brick: These brick are molded to he shape of a gutter or a channel and they are very often glazed. These bricks are used to function as drains.

3. Coping brick: These brick are made to suit the thickness of walls on which coping is to be provided. Such bricks take various forms such as chamfered, half-round or saddle-back.

4. Cow nose brick: A brick molded with a double bull nose on end is known as a cow nose.

Bull nose Channel brick coping brick Cow nose brick

5. Curved sector brick: These bricks are in the form of curved sector and they are used in the construction of circular brick masonry. Pillars, bricks chimneys, etc.

6. Hollow brick: Wall thickness 20-25mm.

7. Paving brick:

8. Perforated brick:

BRICKS MASONRY

It is united mass obtained by systematic arrangement of bricks and bonding them together with mortar. Bricks are a building unit of hard inorganic clay material of a size which can be conveniently handled.

Bricks can be use for various construction purposes and can be easily arranged in various shapes for most of the structures like foundation, walls, columns, buttress, retaining structures, window sells, coping, ornamental brick work, fire places. Tall chimneys, thresholds, steps, floors, arch, etc.

The strength of the brick masonry depends upon the quality of brick and type mortar used.

MORTAR:

Mortar is a pasty material formed by the addition of water mixer composed of an aggugate building material which may be handling with a trowel (thapi). The mortar unites the individual bricks together.

They are different types of mortars in used

1. Mud Mortar

2. Cement Mortar

3. Lime Mortar

4. Cement Mortar

5. Lime Surkhi Mortar

Mud mortar is used for temporary construction.

Cement mortar is used for permanent structures.

In order to select a suitable type of mortar for a given construction. We must know the type of desired finish. The magnitude and mortar of super imposed load.

The effect of the weathering agencies and the important of structures.

In different parts of country, bricks used as length varying from 15cm to 25cm width 9cm to 20cm and the height 5cm to 10cm. Hence separate specifications are available with different department. Indian stand institution has suggested a uniform brick size for the whole country these is popularly known as modular brick normal size of modular brick is 20x10x10cm and the actual size 19x9x9cm.

These bricks are economical to manufacture require less area for drawing.

Characteristics of a good brick:

1. The brick should be compacting homogenous free from holes, crack, air bubbles, flaws, and stone lumps.

2. It should be well burned.

3. It should produced good sound when collides with other brick.

4. It should have uniform colors.

5. It should be tough and hard.

6. It should have finish surfaces on all the sides.

7. Bonding is the process of arranging bricks with mortar to tie them together in the mass of brick work.

8. It should have minimum of vertical joints in any part of the work.

9. It shouldn’t be continuous in two successive courses.

Characteristics of brick bond:

The brick masonry should have the brick of uniform size and shape.

The length of the brick should be equal to the twice the width of the brick. (4.5+4.5=9”).

The use of the brick bat should be discouraged.

The vertical joints in the alternate courses should be vertically above each other.

The stretchers should be only used in the facing while hearting should be done in headers only.

Types of bonding:

1. Header bond

2. Stretcher bond

3. English bond

4. Double bond

5. Single bond

6. Garden bond

7. Facing bond

8. Dutch bond

9. Raking bond

10. zigzag bond

11. English bond

12. Brick on edge bond

13. Bonds in columns

14. Bonds at junctions and squint junction

STONES:

Building stones are obtained from rocks occurring in nature. It is estimated that 3/4th of the land area of the globe is under lane by sedimentary rocks and remaining 1/4th by igneous and metamorphic rocks. The various stone derived from these rocks are

Ø Principle stone from igneous rock are granite or basalt. And trap.

Ø Principle stones from sedimentary stones are sand stone, shale, limestone and lateride.

Ø Principle stones from metamorphic rocks are quartzite, shade, marble, schirt.

Properties of a good building stone:

A good building stone should posses such characteristics:

Ø High strength

Ø High durability

Ø Sufficient hardness

Ø High resistance would be a fire resistance

Ø Specific gravity

Ø Crystalline structure

Ø Low water absorption

Ø Facility for curving and dressing

Ø Weather resistance and better appearance.

Generally stones from igneous and metamorphic rocks are heavier and more durable than stones from sedimentary rocks.

Types and uses of building stone:

1. Granite: It is a very hard and durable building stone suitable for works of importance such as bridge equipments piers etc. where weight and durability are essential. It is not suitable for curving because of its crystalline structure. It is available in these places M.P, H.P, A.P, Maharastra, Assam, Bihar, West Bengle, Jammu and Kashmir, Orrisa, Gujarat, Punjab, Kerala, Rajasthan, and Mysore.

2. Basalt and Trappe: It is a very hard and tough compact and hence expensive in work. It is used in foundation of work usually but may be use for super structures also. It is not suitable for moldings. It is available in Maharastra, West Bengle, and M.P.

3. Sano Stone: It is very easy to dress and work. Extensively used in general construction work. It is available in Andobar Island, Kashmir, M.P, V.P, Rajasthan, and Gujarat.

4. Lime Stone: It is used for flooring roofing, paving. It is used for general building purposes and manufacturing. It is available in Bengle, V.P, Rajasthan, Bihar, Andobar Island, H.P, M.P, V.P, Punjab, and Gujarat.

LATTERIDE: The stone is wet and soft when quartzite and should not be used until season for a month or two for achieving hardness. It is then cutted into rectangular blocks.

QUARTZITE: Silicon sand stones under the effect of metamorphic action. It is a very dense and strong stone with stratified structure and crystalline structure but breaks up into irregular shapes. It is difficult to dress and work. Quartzite is used for rubbled masonry. And also as aggiviate for concrete.

SLADES: These are metamorphic laminated rocks with plane of cleavage along which they can be split into very thin slabs. Slades are used as flooring and roofing material. Harder varieties of slades are used for dado works. These are available in Bihar, Mysore, U.P, Madras, M.P etc.

MARBLE: It is a compact crystalline stone formed by metamorphic stone action. It is one of the strongest and most durable varieties of lime stone. It is obtainable in varieties of colors. Plane or mixed from white to black. It can be easily cutted and curved and takes a high polish. It is extremely suitable for ornamental superior type of building work. It is also suitable for flooring and veneer work. It is available in V.P, M.P, A.P, Rajasthan, Mysore, Gujarat etc.

Suitability of types of stone for engineering works:

Ø Compact sand stones and granite are suitable for building in manufacturing town.

Ø Granites are suitable for building situated for sea shore

Ø Granite and basalt are suitable for paving work

Ø Sand stones, compact lime stone and quartzite are suitable for railway ballast

Ø Compact sand stones are suitable for structure where fire resistance is main requirement.

FLOORING

The purpose of the floor is to provide a level surface capable of supporting the occupant of a building, furniture, requirement and sometimes internal partitions.

A floor must satisfy the following requirement

1. Adequate strength and stability.

2. Adequate fire resistance

3. Sound

4, Damp resistance

5. Thermal insulation

The floor resting directly on the ground surface are known as ground floor while the other floor of each storey situated above the ground level are known as upper floors.

Components of a floor:

A floor is composed of two essential components

1. Sub floor, base case or floor base

2. Floor connecting or simple flooring

The floor base is a structural component that supports the floor covering. Ground floors may either rest directly on the ground or may be supported a little distance above the ground. The floor supported directly on the ground are known as solid floors while the floors supported above the ground level are called suspended floors they are made of timber.

Materials of Construction

Materials used for construction of ground floor are

1. Cement Concrete

2. Lime Concrete

3. Stone

4. Bricks

5. Wooden blocks (for wooden flooring only)

FLOORING OF DIFFERENT MATERIAL

1. Mud and Murram Flooring:

These are used in low cost housing especially in villages. This flooring is cheap, easy to construction and easy to maintain. It has good thermal insulation due to which it remains cool in summer and fairly warmed in winter. Murram is also known as disintegrated rock floor. This flooring has practically the same properties as that of mud flooring.

2. Brick flooring:

Such flooring is used in economical construction where good brick are available. This flooring is essential suited to ware house, stores, go downs etc. well burnt bricks of good colors and uniform shapes are used. (Wire cut bricks are used for flooring).

3. Flag Stone Flooring:

Flag stone is an laminated sand stone available in 2cm-4cm thickness in the form squares (30cmx30cm, 45x45, 60x60.) or rectangular (45x60) this type of work is called paving. (Generally used in exterior landscaping)

4. Cement Concrete Flooring:

This is used for residential, commercial and even industrial building, since the moderately cheap, quite durable and easy to construct. Floor consists of two components 1) Base concrete 2) Topping a wearing surface.

5. Grantithic Finish:

In industrial building hard wearing surface 0’ is sometimes required. This can be achieved by applying grantithic finish over the concrete topping this finish consist of rich concrete made with very hard and tough quality course such as granite, basalt, quartzite etc. The thickness of finish may be minimum 25mm. When laid monolithically with the over hardened surface for public buildings such as schools, hospitals etc. The thickness of finish may be 13mm-20mm.

6. Terrazzo Flooring:

This flooring is another type of floor finish that is laid on the concrete topping. It is very decorative and has good wearing properties due to this it is widely used in residential buildings, hospitals, offices, schools, or other public buildings. Terrazzo specially purposed concrete surface containing cement and marble chips of different colors. The flooring is however bit expensive.

7. Mosaic Flooring: (Chips of stones)

It is made of small pieces of broken tiles of china glazed or of cement or of marble arranged in different pattern. These pieces are cut to desired shapes and sizes.

8. Tile Flooring:

It is constructed in the form of square hexagonal or other shapes. Made of clay (pottery) cement concrete or terrazzo. These are available in the different sizes and thickness. These are commonly used in residential places, offices, schools, hospitals and other public building as an attractive to terrazzo flooring specially where the floor laid quickly (ceramic: made of clay. Top covering is made of porcelain)

(Vitrified: whole tile is made of same material)

9. Marble Granite Flooring:

It is superior type of flooring used in bathrooms, kitchen, sanitary, temples etc, where extra cleanliness is an essential requirement. Usually in rectangular manner as that for concrete flooring.

10. Timber Flooring:

This flooring is used for parliamentary halls, dining halls, auditorium etc. They are not commonly used in residential buildings in India because timber flooring is also quite costlier. In hilly areas where timber is cheaply and readily available and where temperature drops very slowly. Timber flooring is the damp prevention this can be done by introducing the DPC layer below the flooring.

DPC- Damp proof course

(Fixing process: fixed with the help of groove).

11. Rubber Flooring:

It consists of sheets or tiles of rubber variety of pattern and color with thickness varying from 3-10mm. The sheet or a tile is manufactured by mining pure rubber with tiles such as cotton fiber, granulated cork or asbestos fiber. Rubber flooring are resistant and noise proof. However they are costly they are used in offices, public buildings.

12. Linoleum Flooring:

It is a covering which is available in rolls and which is spread directly on concrete or wooden flooring. This sheet is manufactured by mixing oxidized linseed oil in gum resins, pigments, wood flour, cork dust and other filler materials. Linoleum tiles are also available which can be fixed to concrete based or wood floor in different pattern. It can’t be used in bathroom, kitchens etc.

13. Cork Flooring:

This flooring is perfectly noiseless and is used in libraries, theaters, art gallery, board casting stations etc. Cork is the outer bark of the cork oak tree. Available in the form of the cork carpet and work tiles. They are available in various sizes, thickness and shades.

14. Glass Flooring:

It is a special purpose flooring used in circumstances where it is desired to transmit light to the basement from the upper floor. It is very costly and is not commonly used.

15. Plastic or polyvinyl chloride (PVC):

It is made of plastic called polyvinyl chloride fabricated in the form of tiles of different sizes and color shades; these are used in residential as well as non residential buildings. It is smooth and good looking but can be damaged easily when in contact with burning object. Available in 1mm, 2mm, and 3 mm. it is fire retardant.

Silicon Flour- (it is the apoxy) is a powder to dry soon.

White cement- observes dust.

Latierate (white cement only)-it don’t observes dust.

Apoxy- combination of glass thin layer (this can be done on marble to avoid to absorb anything).

GLASS:

Glass could be grouped according to the nature:

GLASS

1. Annealed 2.Toughened 3. Special

a) Sheet Glass Float glass Plate Bent Glass a) Textured

b) Mirror b) Pressed

c) Obscure Glass a) plain c) Perforated

d) Glass Blocks b) Heat excluding d) Glass Bricks

e) Pin Heat Glass c) Safety Glass e) Non-Reflective

f) Plain Glass d) Ultra violet f) Wired Glass

e) Mirror g) Shielding

f) Bulletproof Glass h) Soluble Glass

g) Value added glass i) Fiber Glass

h) Etched glass j) Figured Glass

i) Sand blasted k) Foam Glass

j) Glue clipped l) Stained or col.

k) Acid etched

l) ‘V’ grooming

Glass is made by melting in a furnace at a very high temperature. A mixture of pure sand Fodor and clay with some amount of broken glass and then casting the molten mass into moulds into required shape.

Glass is transparent and hard and its needs to be cut with a diamond edge. The cost of glass depends on two factors.

1. Process of manufacturing, 2. Sizes available

Manufacturing of Glass:

1. Collection of Raw material.

2. Preparation of batch – material should be made in powder.

3. Melting in furnace.

4. Fabrication- Giving shape.

5. Annealing- Cooling.

The glass is a mixture of number of metallic silicates one of which is usually an alkali metal.

Various varieties of glass have been developed in recent times for various purposes and today it is possible to make glass lighter than a cork, softer than cotton or stronger than steel.

The varieties of glass are being used in building industries for various purposes such as walls, ceiling, door, windows, bathroom fittings and furniture’s.

Properties of glass:

1. It is basically hard, transparent and translucent material.

2. The properties such as hardness, fusibility can be change according to their required.

3. It is not affected by ordinary chemical agents like air and water.

4. It is possible to welt pieces of glass by fusions (melting).

5. It provides electric insulation due to uncertain crystalline structure.

6. It absorbs, refracts or transmits lights depending upon the varieties for a particular use.

7. It is available in various colors and shapes.

8. It has no shape melting points. Not effected by weather or heat.

9. It can be fabricated into desired shapes and sizes by heating and cooling.

Kinds of glass:

1. Crown glass: manufactured by means of a blow pipe which is dipped into molten glass and then blown into a globular form which is than detach from the blown pipe which is than rotated on a flat disk until it is plotted out. This is generally convex used for glass tubes electrical bulbs.

2. Sheath glass or plain glass: This is made from blowing glass into a large hollow cylinder. These cylinders are later split longitudinally. This glass is used for windowpanes.

3. Plat glass: This is made by posing white hot molten glass over an iron table and holding it into a uniform thickness. Under a heavy metal roller. This is clear and stronger glass with few or more vitual distraction. This is used for large and small window panes. Mirror, showcases, shops, window displays etc.

4. Fluted or ritted glass: These is a wavy glass with corrugation. It is used where privacy is required light is not obstructed.

5. Wired or reinforced glass: This is basically plate glass with wire netting imbarded in it. It resists fire and doesn’t fall into pieces when fractured. It is used for fire resistance door and windows and skylight.

6. Ground or obscure glass: This is made either by grinding on one side of the glass or melting powered glass upon it. There is used where light is required without transparency.

7. Bullets prove glass: Used for jeweler’s show rooms, bank, wind, shutters of automobiles. This glass is made from at least 4 layers of glass and clear high-test plastic. This is a layer of plate glass joint by vinyl resin used for showcases, jewelers, casher booth etc.

8. Mirror: The other wise transparent surface is made reflect by laying a silver nitrate and ammonia which make a mirror.

9. Flint glass or potash lead glass: This type of glass is used for electrical bulb, optical lenses, table ware etc.

10. Hard glass or potash lime glass: this is used for making glass articles subjected to high temperature.

11. Pyrex glass or borosilicate glass: This type of glass is used in high quality laboratories apparatus and cooking utensils.

12. Common glass or bottle glass: these are used in making medicine bottles.

METALS

Choosing Metals: Its industrial requirement and hardness cool surfaces. Metal may not be seen as an oblivious choice for the home but in contemporary interiors. It is celebrated for those qualities.

Compare with other materials smooth metal finishes can provide pleasing contrast terms of colors, texture, and temperature adding to the sensual enjoyment of a space.

A metal has many uses in the field of construction and interior of home or commercial places etc.

From architectural element such as windows and staircases to kitchens and bathrooms fitting and all kinds of furniture’s and lighting.

Using metal like steel and aluminums to stair raiser, door, units, wall units and even ceiling (steel) create a very modern look or you can choose less commonly metals. Such as Zn, cu, or other surfaces and interior details.

From the environment point of view metal losses marks because of its high embedded energy. A redeemed fixture (good quality fixture) however is that, nearly all metal are recycled.

Metals are classified into two types 1. Ferrous and 2. Non ferrous.

1. Ferrous: These metal contain iron as their constituent and are obtained from iron ores which consists of compounds of irons, non metallic elements (sand, coal) and impurity such as carbon, manganese, phosphorous, silicon, sulphure). The crude impure iron extracted from iron ores is known as “pig iron”.

The properties of these three ferrous metals vary mainly because of its carbon percentage or carbon content in the metal.

2. Non Ferrous: These metals do not contain iron as their main constituent. Some of the non ferrous metal, such as aluminum, copper, brass, zinc, lead have limited use in the building industry.

Ferrous Metals:

Cast iron: It is manufactured by refining pig iron in cupola furnace old casting or scrap iron is sometimes added to improve the quality of cast iron, carbon content in cast iron varies from 1.7 to 4.5%. Cast iron can be readily distinguished from wrought iron. By its crystalline structure, by its want of ductility and its brittleness. Iron is the metal from which many alloys including steel are made and it is how generally used in modern building construction. Cast iron is so called because the molten iron is cast into moulds. It is strong and more resistant to corrosion than wrought iron. In home it is mostly used in bath tubs, fire bags, stove and some types of heavy duty pots and pans.

Cast iron is generally classified into three types:

1. Grey cast iron,

2. White cast iron,

3. Malleable cast iron.

1. Grey cast iron: It is softer and tougher than white cast iron and runs freely into moulds and can be machine. It is generally used for engineering works or ordinary castings.

2. White cast iron: It is very hard and brittle and is unsuitable for general casting into machine. It is mostly used for conversion of wrought iron malleable cast iron.

3. Malleable cast iron: It is annealed (raw) white cast iron from which some of its carbon has been extracted by heating to red hot which makes it stronger less brittle more malleable and ductile than ordinary cast iron. It is softer and tougher than grey cast iron. It is used for door hinges, pipe fitting, and hardware agricultural implements.

Properties of cast iron:

Cast iron is strong in compression. It is brittle and doesn’t observe shocks. When subjected to fire it fails suddenly without giving any warning. It cannot be welded easily or rolled. It cannot be punch like steel but it can be easily melted and cast into various shapes and machined. It melts at a temperature of about 2000deg faranite. It normally offers excellent resistance to corrosion as compared to any other ferrous metal. Cast iron is generally used for making water and seepage pipe, spiral staircases, manholes over rain water pipes, gutters, and sanitary fittings.

Wrought Iron:

It is the purest form of iron with low carbon content less than 0.15% it is made from white cast iron by removing most of the carbon, manganese, silicon, phosphorous, and sulphur. Instead by being cast, this iron is stretched, hammered and twisted when in a hot and semi molten state.

Wrought iron can be used to make gated, windows, balusters, balustrades etc.

It has a tradition image by appointing a skilled craft man. You can get a unique piece of a wrought iron for a specific location.

Properties of wrought iron:

It passes the important quality of toughness ductility and malleability.

It can be easily welded at a temperature of 900deg c and their melting point is above 1500deg f.

It can be bent, twisted when either hot or cold.

Wrought iron rusts more quickly than cast iron.

Wrought iron is replaced at present to a great extend by milled steel.

Steel:

A metal alloy, steel is a mixture of iron with small properties of other metals. Added to enhance the irons performance.

There are many different products made from it and like iron which to date as a strongly traditional image. Steel is the self curiously modern material. So long as it in a dry environment steel should not corrode (become holes) and does not therefore need any special finish.

It can however be coated with paint or oil to seal it and exclude air that night damp (moist).

Steel can also be galvanized or electroplated with zinc to avoid corrosion or coated with a mixture of elements including carbon and copper which create a superficial rusty layer and there by protect the steel venerate.

Steel mesh or steel can be used on walls, stair tread and raiser and to form walkways and clad areas of floor specially where there is heavy traffic, the sheet can be grided or brushed. Usually found in a commercial environment, steel diamond plate flooring brings a modern, industrial quality to living space.

Stainless steel:

Stainless steel is more popular for use in interiors as it doesn’t rust. An alloy containing 20% nickel and chromium as a smooth and shiny finish that is immensely appending. The area of the home in which stainless steel is most widely used is kitchen. Inspired by the streamline, utitarean appearance of professional kitchen.

Designers created a sleek modern for domestic ones.

As the material stainless steel is almost maintenance free, any stains or marks quickly disappear under the friction of a scrub.

Bathroom bases, bathtubs have followed kitchen sinks and units though these are still expensive, exclusive items.

Steel is an alloy or compound of iron and carbon in the form of carboide of iron. The smaller the amount of carbon steel contained, the nearer will be its properties resembling those of wrought iron and greater the amount of carbon it posses nearer it will be approaching in properties to that of cast iron (0.25-1.25).

Properties of steel:

Steel are highly elastic, ductile, malleable, and wieldable. Steel is also flexible at a lower temperature than wrought iron steel have much higher compressive strength than wrought iron, steels are generally used for the following purposes:

1. As structural material in frames beams and light frames in the form of various sections.

2. As nonstructural component is used for grills, stairs, balustrade, windows and doors furniture’s etc.

3. Sanitary fittings.

4. Mechanical service in the form of steel pipes, tables, banks.

NON-FERROUS METALS:

1. Aluminum:

It is bluish, silvery, white lustrous metal obtained from bauxite ore, pure aluminum is very soft and ductile and therefore it is alloyed with other. Metals like copper, magnesium, silicon, manganese etc. which increases its strength and hardness while retaining its characteristic of lightness and durability. Aluminum is highly resistance to corrosion and very good conductor of heat and electricity, its melting temperature is 658deg c. this light weight metal is associated with aircraft and the wheels of sprat’s car. In its iodized form aluminum is porous unlike steel or iron, aluminum resells rusting and is therefore a useful material for windows. Its light weight makes it ideal for cleaning surfaces both horizontal and vertical sheeting can have a simple brushed finish or can be embossed with geometric pattern. Both tiles and sheets can be used to make a light weight floor covering which levels an element of modernity to an interior. There are also a number of designers or light weight chairs or tables and most of door furniture are made from aluminum. It is also used for post panels and balustrade, partitions and for general purpose such as foils, wires.

2. Lead:

It is bluish grey in color with silvery luster when freshly cut. It is obtained from sulphide ore of lead. Lead is a very soft, highly ductile, malleable and non corrodible metal with low fusion point and very low strength. This metal is extremely resistant to atmospheric. Corrosion and is not effected by soil or industrial waste.

Uses: It is used for several purposes like lead sheets for roofing, water services pipes, and soil and gas pipes and for general purposes such as lead oxide for paints making bullets, alloys etc.

3. Copper:

It is attracted by melting coppery rifes (it is an ore of copper). Pure copper is of lustrous red colors and is intensively used for engineering purpose. It is a light strong, ductile and malleable metal with good properties of resistance to corrosion in dry air. It can be forced or rolled or otherwise worked hot and cold and join into wires. It is a good conductor of heat and electricity.

Uses: copper is used for several purpose such as electric wires and cable sheet for roofing, lighting, protective devices, light gauge tubing for hot and cold water supply gas and sanitation services for general purpose such as protective coating for metals electroplating etc.

When it is new copper has a distinctive reddish oranges grow. The metal has a long life easy to work with and has a long uses such as wiring and piping. Copper can be used in kitchen like copper sheeting on the fronts of kitchen units. In the same way other metals and array of copper pans hanging from a rack gives a sticking visual appeals. In out doors copper reacts over times with carbonic acid in rain to acquire the distinctive green corrosion which looks attractive on cladding and roofing.

Brass:

It is an alloy of copper and zinc but various alloys are produced by varying the proportion of these metals and even adding minor proportion of other metals, properties of brass vary considerably by changing these proportions, most commercial brass are ductile and malleable at ordinary temperature and can be rolled into wires or last into moulds. Although colors are bright yellow when fresh but requires regularly cleaning.

Uses: Brass is used for several purposes such as fitting for doors and windows, stairs, grills, and finished hardware in buildings bearings for machinery. House hold utensils, furniture etc.

4. Bronze:

It is alloy of copper, zinc and tin and contains about 80% of copper. They are stronger and superior to brass for corrosion resistance properties. It is difficult to work with bronze and it is expensive.

5. Zinc:

Zinc is a malleable food safe metal. It is traditionally time on the counters of French bars. This metal is soft and abraded by use and so develops an attractive layer. When it is new zinc shade is bright and silvery its softness means the zinc can easily be folded, soldered and pinned over the surtales and around the counter tables, counter top and doors of kitchen units.

Tin: Metallic tin is found to occur in grains intermingled with gold ores of Bolivia, Guinea and Siberia. It is also available in nodules, which are known as ‘stream tin’. The chief of tin ores are tin stones, Stagnates, The Pyrites.

Uses: plating, lining lead pipes. Preparation of alloys and solder. Making evaporation basins, infusion pots etc. it is also used for giving protection coating to copper and iron utensils.

TIMBER:

Timber and its products:

The use of wood is a universal phenomenon. It marks a stage in a civilization of mankind since the dawn prehistoric civilization to the present days.

Wood is used in variety of ways:

Ø Man started his activities in the field of construction with the help of wood.

Ø Later on he made house hold articles, furniture’s, agricultural vehicles, ships and boats, dwells of gods etc. of woods.

Ø The worship is common through out the world.

Besides Asia, it is invoked in some parts, of Africa and laten America.

They are the symbols of prosperity which has been accepted by most of the Indian religion that is why we find a large number of trees motive in Hindus and jains, art and architecture.

Ø Wood as material for construction has been in use since the prehistoric period.

Ø This is proved by large number of exaction.

Ø Wood efforts large slope of decorative art.

Hence, during the historic period. We find large number of beautiful palaces and public building made of wood.

Ø Megasthenes is the Greek ambassador in pataliputra give a picturesque age of chandragupta mauria.

Ø A large place having evidence of the use of wood on large scale was unearthed during excavation at patliputra.

Ø At some places stone pedestals had socitts for the well decorated wooden posts, and at the others chair post, rafters, and lintels of wood were discovered.

Ø Recently the planes of the house of the satavahanas have been prepared with the help of data from excavation at parthon (Greece), bramapuri etc. From their it is evident that the houses were constructed in brick and mud and the roofs are made of tiles fixed on wooden frame. These frames are consisted of wooden rafters and porcelain. Supported by vertical pillars. These rafters are fixed on the top of the walls and covered by terracotta tiles.

Ø Secondly the door and windows were naturally made of wood as compared to stone. As a material of architectural and decorative art wood is easily available.

Ø Smooth and curve able wood on other hand has certain limitation on its use in construction and decoration.

Ø Stone is massive hard and requires great skill to fashion ate or decorate. Comparatively, stone work is more expansive and time consuming. Again, one has to face the problem weight of the structure and its balancing.

Ø During the early face architecture wood was preferred to stone. Despite the good qualities of wood there are certain limitations on the use of wood. Even it is desired well.

Ø Wooden construction doesn’t last for more than two to three centuries. Hence we find that usually the state and public structure are constructed by stone while less building are constructed with maximum use of wood.

Ø Timber being a natural product of India is available leaf and post, cub boards, shelf’s, etc.

Ø Strength characteristics of various types of timber vary one another. Timber generally use in India are bubble, Sal wood, teak wood, blue pine, walnut, deodar, chil, neem, mango, kail, etc.

Generally, the tree from which the timber is obtained is classified in

1. Exogenous, 2. Endogenous.

1. Exogenous: These are the outer growing trees. Trees which include all commercial timbers used for building purposes

2. Endogenous: These are the inner growing. Trees includes such as palm, bamboo. Which are not suitable for engineering view and are found in the tropics

The exogenous trees are divided into hard wood and soft wood.

Hard wood: It has broad leaves and generally dense and narrow, well defined annual rings. They are heavy, strong and hard. They are capable of resisting all stresses equally.

Soft wood: It have long and narrow pointed leaves and characterized by annual leaves which has straight grains more uniform texture and light color. It is very strong for direct pull but weak in resisting sneer.

Structure of Timber:

Bark or Spin: It is the outermost portion of the rings. The outer bark protects the tree from the high temperature and mechanical harm. The inner bark covering the cambium layer protects it from any injury.

Cambium Layer: This layer of sap between inner bark and sap wood is known as ‘cambium layer’. These layers marks bark on the outer side and root on the inner side.

Sap wood: The outer annual rings between cambium layer and heart wood are known as sap wood. It is usually light in color and weight. When compare to heart wood. Sap wood is not used for any engineering work it contain large amount of moisture and liable to quick decay.

Medullary Sheath: It is the layer between heart wood and the pith. It covers the pith from all around.

Pith or Medulla: It is the inner most portion of tree which is very soft portion and varies in size and shape for different types of tree. It consists entirely of cellular tissues.

Properties of good timber:

Strength: The timber should be strong enough to with stand the loads. Whether being applied slowly or suddenly. It should posses enough strength in direct compression and transverse direction.

Durability: A good timber should be capable of resisting the various actions due to the fungi, insects, chemical and mechanical agencies.

Whether resistance: A good timber should process adequate resistance against weather effect such as alternate drying and wetting alternate cooling and heating because of temperature variation.

Fire resistance: The timber should offer sufficient resistance against fire so that it doesn’t easily ignite. It helps in fire protection of buildings.

Elasticity: The timber should be capable of regaining its original shape when load causing deformation is removed. This property is important when timber is to be used to carriage shafts. Sports goods, wooden beams, floors etc.

Word ability: The timber should be easily work able and shouldn’t clag (stuck). It should also be Capable of easily plainned or make smooth.

Toughness and aburation: A good timber should be capable of offering resistance to shocks due to vibration and shouldn’t deteriorate due to mechanical wear.

Other properties of good Timber:

Ø Timber should have sufficient weight. A timber with heavy weight is considered to be sound and strong.

Ø A structure of timber should be uniform hard and compact.

Ø Timber should have sufficient hardness like resistance against penetration.

Ø Timber should have favorable physical characteristic such as dark color, straight fibers, shining appearance, free from defects, swells, smells, good sound when stuck.

Defects of Timber:

Several natural defects occur in all kinds of timber depending upon soil on which they grow and climatic condition to which they subjected while growing. These defects should be avoided or removed as far as possible during conversion for use.

Heart wood:

These are the cracks or splits in the centre starting from pith extending in the direction of modularly rays in one or opposite direction towards sap wood, such defects are found in matured trees but sometimes. They may be caused by quick drying of central part of tree. If a tree nearly maturity is felled and left un-barked for a long time this defect is caused due to shrinkage of hard wood.

Star shakes: These are cracks of splits which extend from bark towards sap wood. This defect is caused when the tree is subjected to severe heat or frost during its growth. The width of these cracks or shakes is more at the outer end and reduces when they extends towards centre.

Cup shakes and Ring shakes:

These are formed by the rupture of tissues in a circular direction a cross section of a log usually along annual rings when the rupture extends only apart around. It is called as cup shakes and the whole way round or almost so it is called ring shakes. This defect is caused either due to unequal growth or due to sudden contraction of timber under atmospheric changes assisted by twisting action due to wind.

Radial Shakes:

These are similar to star shakes but occurs due to exposure to sun. when felled timber is placed for seasoning. These cracks are fine irregular numerous cracks or split run for a short distance from bark towards centre then follow the course of an annual ring and lastly go towards the centre radially.

Ring galls:

These peculiar curved swellings found on living or dead tree generally caused by the growth layer over the wound left after branches have been imperfectly cut off or removed.

Upsets or Ruptures:

These are ruptures of fibers wood caused due to some sought of impact injury or pressure. They are also caused due to unskillful felling and violent wing effect.

Twisted fibers or wandering hearts:

This defect is caused due to tree being twisted constantly in one direction by the force of prevalent wind. This wood is unsuitable for squaring or sawing and hence can be used for posts of poles in un sawn condition or for fuel purpose.

Wind cracks:

These are shakes or splits on sides of a bark of timber due to shrinkage of the exterior surface exposed to atmospheric agencies like sun, wind etc.

Knots:

These are the bases of branches or limbs which are broken or cur off from the tree. The portion from which the branch is removed receives nourishment from the stem for a pretty long time and it ultimately results in the formation of dark hard rings which are known as knots. As continuity of wood fibers is broken by knots. They form a source of weakness.

End Splits:

These are cracks extending from one face to another.

Dead wood:

Timber obtained from dead standing tree (i.e. after maturity) is known as dead wood. It is light in weight deficient in strength and reddish in color.

WOOD:

Types of Plywood:

Ply woods are available in different grades:

1. Commercial plywood

2. Waterproof plywood

3. Marine plywood

4. Shuttering plywood

5. Fire retardant plywood

1. Commercial Plywood: The most common plywood that is used in interiors especially for office and other commercial interiors. This is cheapest variety of plywood available. The problem with the commercial is warping and termites.

2. Waterproof Plywood: The panel boards are dipped in a tank full of waterproofing chemicals thereby sealing the pores and making it waterproof. These are used for wardrobes and other furniture, especially in residential interiors.

3. Marine Plywood: The panel boards are put in a vacuum chamber where chemicals are injected in the boards under pressure and kept in the chamber for 6 hours and then dried. These are used mostly in kitchen counters, toilets doors or outer doors where this plywood would not be destroyed by water.

4. Shuttering Plywood: This special grade of plywood can withstand water up o 30 days for shuttering for the slabs and columns where the concrete is used for 14-21 days.

5. Fire Retardant Plywood: The panels undergo dipping treatments through 6-12 types of chemicals in that many tanks and after drying they became fire retardant. This are used to lint the railway coaches, Bus, Lorries etc.

ADVANTAGES OF PLYWOODS:

a. As plies are placed at right angles to each other, expansion and shrinkage are comparatively very low.

b. They are available in a variety of decorative appearance.

c. They are available in large sizes.

OTHER TYPES OF BOARDS:

1. Chip boards

2. Agro boards

3. Cement boards

4. OSB boards

1. Chip Boards: Small pieces of wood are crushed into small particles and then pressed with resin to form boards. These are cheap but finishing is not good with this boards. These boards are not strong and cannot hold the screw for the long time. These are good for horizontal surfaces. These are also known as particles boards i.e. NOVOPAN, CHIP BOARDS.

2. Agro Boards: These boards are made up of agricultural waste, sugar cane waste (pulp). These materials are also crushed into minute particles and pressed into boards with resin bordering. These boards are not very strong and the screw holding capacity is not good. These are also types of particle boards and are also called as Medium Density Fiber Boards or MDF as they are made of fibers, used for horizontal surfaces, wall paneling. E.g.: ECOBOARDS. (Made of pulp), NUWUD (cotton waste) etc.

3. Cement Boards: Crushed particles of wood is bonded with cement and converted into boards. These are very strong and water resistant, can be used for outer walls, false ceiling, out doors roofing for gazebos, wall paneling in damp areas, etc. those being made in cement does not give good finishing when cut and a bit difficult to handle by the carpenters. E.g. BISON boards of NCL INDIA, HYD.

4. OSB Boards: These are oriented strand boards. These boards are made up of strands of wood, about 30mm-45mm long and oriented such they are in the form of alternate grains. This makes the OSB extremely handy to use, as the screw holding capacity is as good as the plywood. These are usually made in Germany and are used for roofing. Hence, they have excellent water proofing character and look very attractive. When used for doors, all they need is papering and a coat or two of hand spirit polishing and staining if necessary, because the soft wood strands make beautiful pattern on the surface.

5. Particle Boards: Chips obtained by crushing TW (Timber wood) are seasoned are mixed with phenol. Formaldehyde and synthetic resin and spread on a plate in three layers. The middle layer contains thick chips while the outer ones contain thin chips. Nova pan uses urea and formaldehyde while Indian plywood uses only formaldehyde.

VARITIES OF TIMBER FOUND IN A.P:

Bamboo: It is an endogenous tree. It is flexible, very strong and durable. It is used for scaffolding, thatched roofs, rafters, temporary bridges, fancy goods etc.

Rose Wood or Black Wood:

It is dark in color. It is strong, tough and close-grained. It is handsome and it takes up a high polish. It maintains its shape well. It is available in large sizes. Its weight after seasoning is about 7900N/M3. It is used for furniture of superior quality, cabinet work, ornamental carvings, etc.

Teak Wood: Characteristics of teak wood are golden to dark brown, reddish brown, with a straight grain. Without protective finish, teak like most hardwoods exposed outdoors or in gardens environments. Will turn a silvery gray color. It is one of the world’s most naturally durable and stable woods. It is fire resistance. It can be easily seasoned and worked. It takes good polish; it is not attacked by white ants and dry rot. Its use is limited to superior work only as it is comparatively very costly.

Casuarinas: Its color is reddish brown. It grows straight. It is strong and fibrous. It is, however, badly twisted. It is used for scaffolding, posts for temporary structures, etc.

Tamarind: Its color is dark brown, it is knotty and durable. Its development is very slow. But it ultimately forms a massive appearance. Its fruits are also very useful. It is used for agricultural instruments, well kerbs, sugar mills, carts, brick moldings, etc.

Sissoo: It is also known as the shish or tail. Its color is dark brown. It is strong and tough. It is durable and handsome. It maintains its shape well. It can be easily seasoned. It is difficult to work. But it takes a fine polish. It is used for high class furniture, plywood’s, bridge piles, sport foods, railway carriages, etc. it is very good material for decorative works and carvings.

Banyan: Its color is red. It is soft and even grained. It is durable in moist places and under water. It takes a good polish. It is used for furniture, door panels, well kerbs, piles, railway sleepers, bridge construction, etc.

Pine: It is hard and tough except white pine which is soft. It decays easily, if it comes in contact with soil. It is heavy and coarse grained. The white pine is light and straight grained.

Palms: It contains ripe wood in the outer crust. The color of this ripened wood is dark brown. It is strong and durable. It is fibrous. It is used for furniture, roof covering, rafter, joists etc.

Mango: The mango tree is very well known for its fruits. Its color is deep grey. It is easy to work. It maintains its shape well. It is moderately strong. It is used for cheap furniture, toys, packing boxes, ship building, cabinet work, panels for doors and windows, etc.

Guava: It is fine grained. It is hard, tough and flexible. Its color is grayish brown. It is not very strong. It can be easily worked. It is used for making toys, handles of instruments, engraving work, etc.

Bijasal: Its color is light brown. It is coarse-grained, durable and strong. It is difficult to work. It is not easily attacked by white ants. It is used for ordinary building construction, cart wheels, etc.

CURTAINS

Furnishing and Upholstery (Window Dressing)

Ø Curtains

Ø Curtain Rod

Ø Pelmet (to cover the rod)

Ø Rings

Ø Tie backs or hold back

Ø Brackets

Ø Top Dressings

Ø C- Channels

Ø Tassels (Bunch of threads)

Ways

Ø Curtains

Ø Shades and Blinds

Ø Valences and Swags(top portion of the window)

Ø Accessories

Ø Hangings

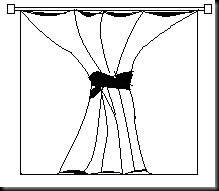

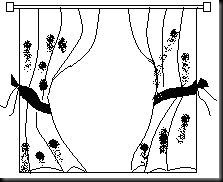

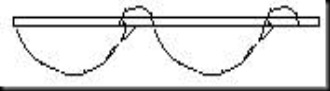

Types of Curtains:

Ø Sash Curtain

Ø Café Curtain

Ø Smoke Curtain

Ø Plain Curtain

Ø Single/Double Curtain

Ø Pleated Curtain

Ø Tiered Curtain

Ø Long Curtain

Ø Top Rod Drapers

Ø Strap Curtain

Ø Sheer Curtain

|

Sash Curtain: |

Plain Curtain: |

|

Cafe Curtain: |

Smoke Curtain: |

|

Single/Double Curtain: |

| Pleated Curtain: | Tiered Curtain: |

| Strap Curtain: | Sheer Curtain: |

Shower Curtain: It is made up of P.V.C

Fabric commonly used for curtains:

Ø Cotton

Ø Polyester

Ø Net

Ø Casement (khadhi)

Ø Linen

Ø Silk

Ø Satin

Ø Jute

Ø Jute Silk

Ø Cotton Silk

Ø Terry Voiles (lining cloth)

Ø Velvet

Ø Jacquards (sofas cloth)

Top Treatment of Windows:

Ø Valances

Ø Swag

Ø Cascade arrangement

Types of Swags:

Ø Wrapped

Ø Open

Ø Gathered

Ø Pleated

Ø Running

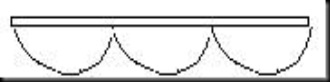

Types of Valences:

Ø Gathered

Ø Box Pleated

Ø Balloon Cloud

Ø Lambrequins

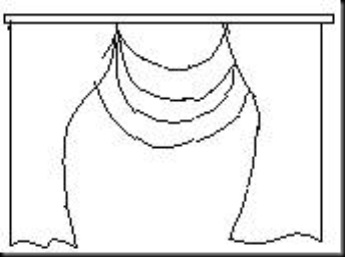

Swags:

Wrapped:

Open:

Gathered:

Pleated:

Running:

Upholstery- Cloth fixed to the furniture.

Furnishing- Cloths used on the furniture.

Blinds and Shades:

Blinds - P.V.C, Wood, or Canvas.

Blinds are calculated in Sq Ft.

Shades- Cloth is used. Lowered blinds.

Window Dressing:

CAPENTRY AND JOINARY:

Technical Terms:

1. Chamfering: Finish cutting for blocks.

2. Planning: To make the surface plane.

3. Plank: Sheet of wood.

4. Housing: Fixing into each other.

5. Screwing: Joining the portion with screws.

6. Rebating: Cutting and joining.

7. Beading: Thinner pieces of <3”. For decorative purpose.

8. Battern: Horizontal legends.

9. Veneering: Sticking the slice of wood.

10. Seasoning: Procedure of storage of wood.

11. Framing: Making a border limit.

12. Overlapping: To make one on the other.

Types of Joints:

1. Lengthing or Longitudinal: Join of two pieces horizontally.

2. Fishing:

3. Notching: Any joint done at 90deg beside each other, overlapped inside.

4. Angular: The joint at any

5. Housed: First portion is interested into the other. But still it will be visible at the equal level.

Dovetailed, tongue, Oblique, angular are load bearing

6. Dovetailed: For bridge, Furniture joint.

7. Framing: For door and windows.

8. Oblique shoulder: One thinner piece is inserted into the two pieces.

9. Butterfly: Pieces of battern joint with the help of metal strip or ledge.

10. Tongue or Grooved: One of the joint is inserted into other.

11. Widening and Side joint: Type of framing.

TYPES OF DESIGNING CONCEPTS:

Zen Style: More of Geometrical shapes (angles).

Victorian: More of Traditional things like chandeliers, fire place, glossy items, curving, and wood is used more and crystal.

Edwardian: Related to Victorian, glass, dark and harsh colors.

Traditional: Completely historic.

Indian (south and north): Mud, mirrors, silk, bandhi cloth, silver, terracotta. S.I- Brass, copper, greenery, and cotton mixed silk.

Chinese: Low level furniture, no curving, red color, dragons, crockery collection.

Japanese: Full height furniture’s, dark colors, candles etc.

Mughal Style: Golden, very more curving, silver articles, ceramic pots, heavy curtains, embroidery, natural stones, ceilings mirror, carpets.

Western: combination of steel and glass, bright colors, different textures, tiles flooring, cheeks and strips patterns, tertiary colors.

Modern: Leather, glass, steel, non colors and primary colors.

Contemporary: Present and traditional mix, heaviness less usage of material. Every space having usage.

Roman: Lamps and shades, full wall window, arches, rockery, bright colors.

French: Light colors with curving furniture, wooden flooring.

Country Side: More of natural things, greenery, stones, rustic effect ion, no polish, rugs, painted furniture, no silk.

The place above fire place is mantle piece.

The wall divides the paint with some biding is called “dado rail”.

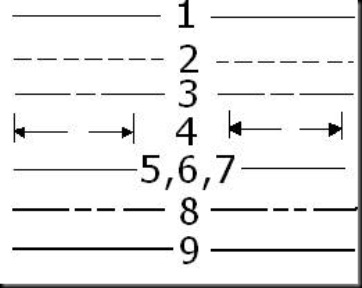

TYPES OF LINES, LETTERING, AND DEMENSIONING:

The various types of lines used in engineering drawing are given below

1. Principal lines or outlines: Lines drawn to represent visible edges and surface boundaries of objects are called outlines. In geometrical drawings, these lines show the final shape of the required figures. They are continuous lines.

Pencil lines Ink lines

2. Dotted or dashed lines: Hidden edges are shown in a drawing by dotted lines. These lines are made up of short dashes of approximately equal length (about 1/8th) and spaced at equal distance of about 1/32”. When a dotted line meets or intersects another dotted line or the outlines their points of meeting or intersection should be clearly shown.

3. Centre lines: Centre lines are drawn in the centers of figures which are symmetrical on two or all the four sides of their centers. They are usually extended about ½” beyond the boundary of the figure. They are composed of alternately long and short dashes, spaced approximately 1/16” apart. The short dashes are about 1/8” in length and the longer dashes about 6-8 times the short dashes. The points of intersection between two center lines must be clearly indicated.

4. Dimension lines: These lines are continuous but broken at a suitable place with sufficient gap for inserting dimensions. They are terminated at the outer ends by pointed arrow heads, partly filled-in and touching the out-lines or extension lines.

5. Extension lines: These are continuous lines. A gap of about 1/16” is kept between these lines and the out-lines of the drawing. They extend by about 1/8” beyond the dimension lines.

6. Construction lines: These lines are drawn for constructing drawings and they are shown in geometrical drawings only. They are continuous lines.

7. Section lines: These are continuous lines inclined at 45degree and spaced uniformly about 1/16” apart.

8. Cutting-plane lines: The location of a cutting plane is shown by a line made up of alternately a long dash and two short dashes in the ratio of about 8:1, the short dashes being approximately 1/8” long, with uniform gap of a bout 1/16” between them.

9. Border lines: These are continuous lines thicker than the outlines of a drawing.

Thickness and shade of lines:

In pencil drawings all lines are drawn thin. The outlines should be intensely black and they should form an outstanding feature on any drawing. The dotted lines should be black and all the other lines grey.

In ink drawings, the outlines are drawn thick, dotted lines of medium thickness and all the other lines thin, the ratio of their thickness being 3:1-5:1.

In this book, in addition to the above lines, other lines made up of alternately a dash and a dot, or a dash and two dots etc. have been drawn in some figures, merely to distinguish them from other lines.

Lettering: Writing of titles, dimensions, notes and other important particulars on a drawing. However accurate and neat a drawing may be drawn, its appearance is spoiled and some times its usefulness is impaired by poor lettering. Lettering should therefore be done properly in clear, legible and uniform style. It should be in plain and simple style so that it could be done freehand and speedily. Use of drawing instruments in lettering takes considerable time and hence it should be avoided. Efficiency in the art of lettering can be achieved by careful and continuous practice.

Single-stroke letters: These are the simplest form of letters and are usually employed in most of the engineering drawings. The word single-stroke should not be taken to mean that the letter should be made in one stroke without lifting the pencil. It actually means that the thickness of the line of the letter should be such as is obtained in one stroke of the pencil. The horizontal lines of letters should be drawn from left to right and vertical or inclined lines, from top to bottom.

Dimensioning: The detailed technique of dimensioning will be described are as follows:

1. Dimensions should be placed outside the views except when they are clearer and more easily readable inside.

2. Dimension lines should not cross each other.

3. Dimensions should not be shown between dotted lines as far as possible.

4. Dimension lines should be placed at least ¼” from the outlines and from one another.

5. Arrow head should be pointed and filled in. it should be about 1/8” long and its maximum width should be about 1/3 of its length. The arrow head is drawn freehand with two strokes made in the direction of the point and the space between them neatly filled up.

6. Dimension figures are inserted in the break provided in the dimension lines. They are usually placed perpendicular to the dimension lines, and in such a manner that they can be read from the bottom or right hand side. The dividing line of fraction is drawn in line with the dimension line.

COLOUR THEORY:

Topics

1. primary color

2. Secondary color

3. Sub-secondary color

4. Tertiary color

5. color wheel

6. Tints

7. Shades

8. Complementary color

9. Contrast color

10. Analogous color

11. Monochromatic color

12. Achromatic color

13. Greyish color

14. Neutral color

15. Warm color

16. Cool color

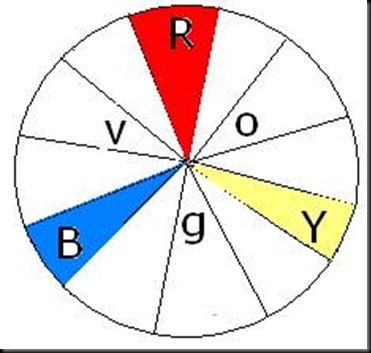

1. Primary colours: colours formed by themselves are formed in nature are called “primary colours”.

* Crimson red

* Lemon yellow

* Cobalt blue

2. Secondary colours: Mixing of any two primary colours. We get “secondary colours”.

*Red +Yellow = Orange.

*Yellow +Blue = Green.

*Blue+ Red = Voilet.

3. Sub-secondary colours: Mixing of primary colours in more or less quantity we get sub secondary colours.

*More of Red + Less of Yellow = Reddish Yellow

*More of Yellow + Less of Red = Yellowish Red

*More of Yellow + Less of Blue = Yellowish Green

*More of Blue + Less of Yellow = Bluish Green

*More of Blue + Less of Red = Bluish violet

*More of Red + Less of Blue = Reddish violet

4. Tertiary colours: Mixing of secondary colours we get tertiary colour

*Orange + Green = Olive Green

*Green + Voilet = Grey

*Voilet + Orange = Brown.

5. Colour wheel:

6. Tints: Adding more quantity of white to all colours (primary, secondary, sub-secondary, tertiary) we get tints.

*Red + White 1:1

*Red + White 1:2

*Red + White 1:3

Up to

*Red + White 1:7.

7. Shades: Adding quantity of black to all the colours we get shades.

8. Contrast/Opposite colours: Colours which are not present in the formation of secondary colour.

*Red *Green

*Yellow *Voilet

*Blue *Orange

10. Complementary Colours:

*Red *Green

*Reddish Yellow *Bluish

*Orange *Blue

*Yellowish Red *Bluish Voilet

*Yellow *Voilet

*Yellowish Green *Reddish Voilet

11. Analogous colours: Colours besides primary colours are Analogous

Colours.

R.V---R---R.Y

Y.R---Y---Y.G

B.G---B---B.V

12. Monochromatic Colours: Two tins and two shades of all colours we called monochromatic colours.

R+W 1:2

R+W 1:1

Red

R+B 1:1

R+B 1:2

13. Achromatic Colours: Grey colours tints and shades of group are called Achromatic Colours

G G G

+ R +

W E B

1:5 1:4 1:3 1:2 1:1 Y 1:1 1:2 1:3 1:4 1:5

14. Greyish Colours: Adding grey colour to primary, secondary colour

We get grayish colour.

Red + Grey = Reddish Grey

Yellow + Grey = Yellowish Grey

Blue + Grey = Bluish Grey

Orange + Grey = Greyish Orange

Green + Grey = Greyish Green

Voilet + Grey = Greyish Voilet

15. Neutral Colours: Adding tints of black to primary, secondary. We

get neutral colour

Red + Black Orange + Black

Yellow + Black Green + Black

Blue + Black Voilet + Black

16. Warm Colours: Shades of Red, Yellow, Orange

Red + Black

Yellow + Black

Orange + Black

17. Cool Colours: Colours starting from green to violet.

Green --- Bluish Green --- Voilet

Bluish Voilet --- Green.

PAPER- 1

1. Introduction to interior designing (purpose)

2. Design concept

3. Lines, lettering

4. Orthographic Projection ‘2d’

5. Metric Projection ‘3d’

6. Color theory, wheel

7. Carpentry and joinery

8. Types of kitchen

9. Doors and Windows

PAPER-2 (Materials)

1. Wood

2. Metal

3. Glass

4. Laminates, Ply wood

5. Tiles

6. P.O.P

7. Curtains

8. Paints

9. Carpets and rugs

10. Bricks

11. Upholstery

12. Hardware

13. Landscaping.

PAPER-3 (Services & Estimations) PAPER-4 (Particles)

1. Staircase 1. Concept Designing

2. Electrical Layout 2. Product “ “

3. A.C 3. Furniture “ “

4. Acoustics 4. Specification of material

5. Plumbing

6. Ceiling PAPER-5

7. Flooring. 1. Portfolio

2. Viva Voce.

![clip_image034[1] clip_image034[1]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEjdiCLGg_MN5YBLTycCwxIBEVSkOEBeeEOjatd8HnTKwtLXdmlGoLuJp2uiMREuo4c5213I8q7AI2CQtEdLSwhA_ODpXv4v0iy2qyoiKPZGnx72vMIlrwGIDLzr58jjJ-EZhhSAsNnaoAY/?imgmax=800)